Approximately 200,000 tons of coffee grounds are produced annually. About 30% ends up in offices or the hospitality industry. These 60,000 tons are usually disposed of as residual waste and incinerated in waste incineration plants. This releases approximately 8,000 tons of CO2e into the atmosphere.

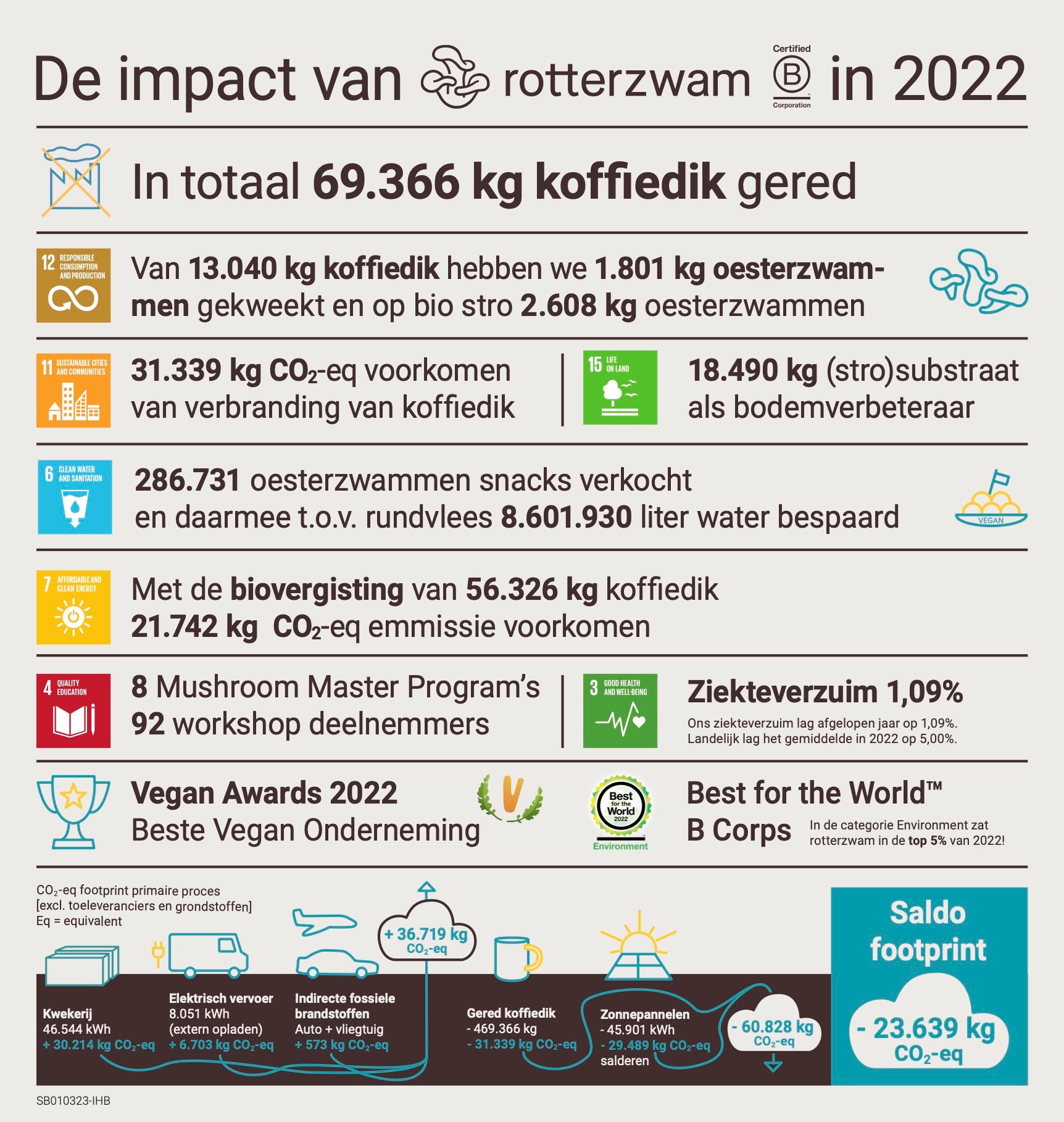

Rotterzwam strives to save as much coffee grounds as possible from incineration. We recover the coffee grounds generated by offices and restaurants and use them as a substrate for edible mushroom cultivation. This circular food is a good meat substitute and contributes to the transition to consuming more green proteins.

Since 2013, Rotterzwam has been collecting coffee grounds within a 50-kilometer radius of the Rijnmond region using electric vans. The entire nursery is equipped with solar panels, making the entire operation 99% self-sufficient in electricity and 100% fossil fuel-free. We are preparing a fertilizer application to have our post-cultivation residual material accredited as fertilizer, allowing it to be returned to the soil as a soil improver and to fix CO2 in the soil.

For the 70% of coffee grounds that are generated by consumers, we've developed a grow kit that allows them to convert this waste stream directly into mushroom substrate on their kitchen counter. Over 100,000 units of this product have already been sold in the Netherlands, and it's now available in several European countries.

The rotterzwam method is based on the natural system of survival of the fittest. Once the coffee bean is ground, hot water is poured over it, and the coffee is brewed, a clean breeding ground for mold is created. Every cubic meter of air contains 1,000-10,000 spores of various fungi. From that moment on, the spores in the air or in the space where the coffee grounds end up seize their opportunity, and competing fungi will try to colonize the coffee grounds. If rotterzwam can receive the coffee grounds within a very short time, we can add our fungus, which will eventually cause edible mushrooms to grow from the coffee grounds. The longer it takes for rotterzwam to colonize the coffee grounds, the greater the chance that other fungi will grow, and the chance of rotterzwam's success decreases, resulting in a high number of losses. Rotterzwam often collects coffee grounds three times a week. Normally, that should be sufficient to collect fresh coffee grounds. This freshness also has a lot to do with the internal logistics within a company where the coffee is made.

Since COVID, we've noticed that the coffee grounds we collect are less fresh. This means they're delivered to us a few days late and now have to be rejected because mold is already visibly starting to grow, making them unsuitable for our mushrooms.

The reason the coffee grounds are less fresh is likely due to lower office occupancy and fewer available workstations for maintaining (and therefore emptying) the coffee machines. The infection, caused by a common fungus (trichoderma), is common in the air and has ample opportunity to grow in the fresh coffee grounds.

We would come by more often This is possible at companies, but in practice, it turns out to be less effective and too expensive. It takes a lot of time to visit these locations, and even then, we remain dependent on the frequency of emptying the coffee machine on-site. We believe a solution is to pasteurize or sterilize the coffee grounds again to kill or weaken competing fungi, allowing our fungi to colonize the substrate more successfully.

Rotterzwam currently collects 7 tons of coffee grounds per month from companies. Currently, we have to reject >75% of the coffee grounds because there is already too high a risk of infection or visible infection is already present. We expect that after pasteurization, we will reduce the rejected coffee grounds from 75% to <25%. This means that of the 7 tons, we can currently only use 1.8 tons. After treatment, we expect to be able to use at least 5 tons.

Of every kilogram of coffee grounds, 20% is converted into mushrooms. So, in this way, we can grow from 1,800 kg * 20% = 360 kg of mushrooms to 5,000 kg * 20% = 1,000 kg of mushrooms.

This means that our mushroom yield could increase by almost three times.

We will need to investigate how we can pasteurize the coffee grounds. Which machines are suitable for this? At what temperature and for how long should we pasteurize? How can we better estimate when it no longer makes sense to reject coffee grounds because pasteurization will yield too little due to the high contamination levels? On what scale will we implement this process? We anticipate that the final investment for this pasteurization may be too large for our small-scale substrate production. We want to investigate whether it would be economically better to establish a central substrate production facility for multiple nurseries in the region.

If this works, it will mean fewer transport movements. It might be possible to collect the coffee grounds only once a week. That could save 2,000-1,500 km per month. And therefore 80% less coffee grounds would need to be transported for fermentation. This is the current situation; if rotterzwam cannot process the coffee grounds itself, they are sent for fermentation.

We submitted the above project proposal to the ERDF program "Kansen voor West" (Opportunities for the West) and received approval to implement this project in 2023. This means part of the project will be funded by "Kansen voor West" and the EU.

We will share project developments via our website.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.